Smart Tangibles News Digest #2504

- Yoel Frischoff

- Dec 1, 2025

- 6 min read

Updated: Dec 5, 2025

Issue #4, December 1, 2025

Welcome to this week’s #SmartTangibles digest - covering #ProductStrategy, #DigitalTwins, #ConnectedHardware, #EdgeAI, #SmartBuildings, #IoTPlatforms and the signals shaping next-generation products. Enjoy!

1. Digital Twins Take Center Stage at IoT Tech Expo Global 2025

Digital twins are emerging as a core Expo theme, evolving from industrial simulation tools into real-time virtual representations of hardware fleets. They now combine telemetry, wear models, environmental inputs, and service history to predict failures, automate maintenance, and optimize performance.

This shifts fleet management from monitoring to lifecycle intelligence, where the twin becomes the main interface for uptime, service delivery, and recurring revenue.

2. Bosch expands its sensor-as-a-service ecosystem

Bosch is extending its sensor-as-a-service platform with new air-quality, vibration, and occupancy modules. Instead of selling components, Bosch is packaging validated insights with APIs and analytics, turning low-margin hardware into high-value recurring services.

This follows a broader shift: customers want data outcomes, not devices.

3. Google releases low-power AI models for on-device inference

Google introduced ultra-efficient AI models designed for microcontrollers and low-power edge devices. These support wake-word detection, anomaly monitoring, and gesture recognition on milliwatts of power.

The result: smarter, more private, more responsive devices without cloud dependence or battery sacrifices.

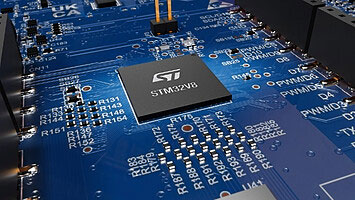

4. STMicroelectronics unveils STM32V8 – the first 18nm MCU for AI-ready embedded systems

STMicroelectronics announced the STM32V8, the industry’s first microcontroller unit (MCU) built on an 18 nm process, marking a major performance leap for edge and embedded devices. Designed for industrial control, robotics, sensor fusion, voice interfaces, and on-device AI, the V8 line brings SoC-class capabilities into the footprint and power envelope of an MCU.

Beyond raw compute, the platform is engineered for low-latency inference, secure operation, and long-term firmware evolution — all essential pillars for next-generation smart tangibles. With this launch, ST is pushing MCUs further into the territory once dominated by application processors, enabling hardware makers to deliver smarter, faster, and more service-ready devices without compromising battery life or BOM simplicity.

5. Schneider Electric launches AI-powered unified platform for building operations

Schneider Electric introduced EcoStruxure Foresight Operation, a unified, AI-powered platform designed to bring HVAC, lighting, energy management, occupancy analytics, and maintenance workflows into a single operational environment. The system builds on the company’s EcoStruxure architecture but adds a strong layer of predictive insights, automation, and cross-system intelligence.

The strategic shift is clear: buildings are moving from fragmented subsystems to software-defined infrastructure, where connected devices act as service nodes inside a continuous optimization loop. For hardware manufacturers, this sets a new bar. Value increasingly depends not on individual components, but on how seamlessly they plug into open, AI-driven orchestration layers that facility teams use to reduce cost, boost uptime, and manage sustainability targets.

#SmartTangibles #SmartBuildings #AI #BuildingAutomation #EcoStruxure #ConnectedInfrastructure #HVAC #EnergyManagement

News In Detail

1. Digital Twins Take Center Stage at IoT Tech Expo Global 2025

One of the strongest signals emerging from the IoT Tech Expo Global 2026 agenda (London, February 5–6) is the accelerating rise of digital twins as the operational backbone for connected hardware and smart infrastructure.

What started as factory-floor simulation is now evolving into live, cloud-linked representations of devices, buildings, and entire systems. The 2026 programme highlights twins not as add-ons, but as the core of how next-generation IoT products will be monitored, serviced, and continuously improved.

Major vendors are already shifting in this direction:

Microsoft Azure Digital Twins

Extending from industrial IoT into energy systems, smart buildings, and multi-device orchestration.

Amazon Web Services (AWS) IoT TwinMaker

Fusing sensor data, maintenance logs, 3D scenes, and ML models to power unified operational views.

Siemens Insights Hub

Siemens extends digital-twin capability through Insights Hub, its open, cloud-based Industrial IoT platform that connects machines, sensors, and entire production environments into a unified operational model.

By linking live telemetry with historical data, analytics, and simulation, it enables manufacturers to monitor assets, optimize performance, detect anomalies early, and run continuous improvement loops across fleets and facilities.

NVIDIA Omniverse

Moving from design simulation to “live twins” for warehouses, factories, and autonomous robotics.

#IoT #DigitalTwins #TechExpo #ConnectedHardware #SmartInfrastructure #CloudLinked #IndustrialIoT #Microsoft #AzureDigitalTwins #AWS #IoTTwinMaker #Siemens #InsightsHub #NVIDIA #Omniverse #LiveTelemetry #OperationalViews #PerformanceOptimization #ContinuousImprovement

2. Bosch Expands its Sensor-as-a-Service Ecosystem

Bosch is accelerating its shift from component supplier to data-and-insights provider, expanding its sensor ecosystem with new air-quality, vibration, occupancy, and environmental modules. Rather than selling standalone sensing hardware, Bosch is increasingly packaging continuous, validated data streams delivered through cloud tools and APIs – a service-led approach designed to plug directly into building-management systems, industrial IoT platforms, and digital twins.

Bosch’s environmental line – including IAQ sensors, VOC/CO₂ modules, humidity/temperature sensors, and the widely used BME series – now integrates tightly with the company’s software and analytics environments:

Environmental sensors:

Motion & vibration sensors:

Sensing solutions for wearables:

This shift restructures the economics: customers increasingly pay for reliability and visibility, not just devices. Facilities teams receive continuous insights – air quality, space utilization, vibration anomalies, ambient conditions – without managing calibration, firmware, or hardware refresh cycles. For Bosch, this turns low-margin components into recurring revenue streams, powered by data ownership and interpretation.

Across the sector, the pattern is unmistakable: as connected hardware matures, value moves upward into the data and intelligence layer. Bosch’s evolution shows how traditional hardware leaders can build defensible, service-led models by delivering not sensors, but trusted, actionable sensor intelligence.

#Bosch #DataInsights #SensorEcosystem #AirQuality #VibrationSensors #OccupancyModules #EnvironmentalModules #IoT #CloudTools #APIs #BuildingManagement #IndustrialIoT #DigitalTwins #IAQSensors #VOC #CO2Modules #HumiditySensors #TemperatureSensors #BMESeries #MotionSensors #WearableTech #ContinuousInsights #DataOwnership #ServiceLed #RecurringRevenue #SensorIntelligence

3. Google Releases Low-Power AI Models for On-device Inference

Google has unveiled the Coral NPU, a next-generation, ultra-efficient AI accelerator designed to bring high-performance neural processing directly onto constrained hardware — from IoT nodes to wearables, AR glasses, and smartwatches.

Unlike earlier architectures, Coral NPU is built as a full-stack platform: custom silicon, optimized runtime, compiler, tooling, and reference designs. This integration lets developers deploy powerful ML models on devices with limited battery and thermal budgets – without relying on cloud inference.

The architecture is optimized for multiple model types (vision, audio, sensor fusion) and dramatically reduces energy per inference. This makes it possible to embed real-time AI into products running on coin cells or compact wearables, while keeping latency low and sensitive data fully on-device.

Potential Applications:

Smart tags and asset trackers with onboard anomaly detection

Environmental sensors that classify conditions locally

Body-worn devices with continuous inference

AR/VR accessories that need sub-10ms responsiveness

IoT nodes that cannot depend on cloud connectivity

For hardware teams, the implications are clear: the frontier of edge AI is shifting from “tiny models” to tiny accelerators. Coral NPU creates a new class of smart, low-power products where intelligence is baked directly into the device, not streamed from the cloud.

#CoralNPU #LowPowerAI #OnDeviceInference #AIAccelerator #wearables #ARGlasses #Smartwatches #EdgeAI #machineLearning #EnergyEfficiency #RealTimeAI #AnomalyDetection #EnvironmentalSensors #BodyWornDevices #ARVR #IoTNodes #CloudIndependence #TinyAccelerators

4. STMicroelectronics unveils STM32V8 – the first 18nm MCU for AI-ready embedded systems

STMicroelectronics has introduced the STM32V8, the industry’s first 18 nm microcontroller, marking a major architectural shift in what MCUs can deliver for edge AI, robotics, smart devices, and industrial systems.

The move to 18 nm brings application-processor-level performance into an MCU footprint, enabling advanced workloads – computer vision pre-processing, sensor fusion, real-time decision loops, and low-latency AI inference – while keeping the ultra-low-power characteristics that STM32 is known for.

The STM32V8 platform is engineered as a full-stack compute solution for modern embedded AI:

High-performance MCU core with fast DSP and math acceleration

Advanced memory architecture tuned for ML workloads

Integrated security for firmware integrity and device identity

Tight coupling with STM’s edge AI toolchain (NanoEdge AI Studio)

Support for complex peripherals used in robotics, mobility, and industrial control

The result: richer intelligence and tighter control loops – without a jump to heavier SoCs.

STM positions the V8 line for emerging “physical AI” use cases requiring instantaneous, deterministic responses:

Autonomous robots and robots

Industrial drives and motion systems

High-speed motor control

Smart sensors with on-device classification

Embedded vision nodes

Energy-optimized devices with predictive capabilities

For hardware teams, the STM32V8 signals a new category: AI-capable MCUs that blur the boundary between microcontrollers and full application processors. Devices can now run sophisticated ML/analytical workloads locally, maintain strict energy budgets, and support long-term firmware evolution without redesigning the hardware platform.

This is edge intelligence becoming native to the MCU layer.

5. Schneider Electric launches AI-powered unified platform for building operations

Schneider Electric introduced EcoStruxure Foresight Operation, a unified, AI-powered platform designed to bring HVAC, lighting, energy management, occupancy analytics, and maintenance workflows into a single operational environment. The system builds on the company’s EcoStruxure architecture but adds a strong layer of predictive insights, automation, and cross-system intelligence.

The strategic shift is clear: buildings are moving from fragmented subsystems to software-defined infrastructure, where connected devices act as service nodes inside a continuous optimization loop. For hardware manufacturers, this sets a new bar. Value increasingly depends not on individual components, but on how seamlessly they plug into open, AI-driven orchestration layers that facility teams use to reduce cost, boost uptime, and manage sustainability targets.

#SmartTangibles #SmartBuildings #AI #BuildingAutomation #EcoStruxure #ConnectedInfrastructure #HVAC #EnergyManagement

This news digest is compiled weekly. Register here to receive it in your inbox.

Comments